Commissioning processes are being introduced to new and old participants in the construction field daily. One of the more essential portions of the commissioning process, system verification checklists (SVCs) also known as pre-functional checklists (PFCs), can at times lead to tension with the Construction Team. Complaints range from “too time consuming” to “too repetitive” and many voiced opinions in between. Although it can be a difficult task to get complete buy-in from the team, the system verification checklists are imperative to providing the Owner with the specified finished product. There are few things a Commissioning Authority (CxA) can do or use to ease the process for the team and keep the project on the right track.

A Key Step for Successful Commissioning

It is important that the CxA prioritize system verification checklists at the beginning of each project. A CxA should make a significant effort to provide all applicable team members with login information to the database used to complete the checklists ahead of the commissioning kickoff meeting. In a perfect world, each team member would take this time to login to the system to verify access and potentially attempt to navigate to individual checklists. This is typically wishful thinking, but it is our job as the CxA to make sure all team members have the necessary tools to successfully aid in the commissioning process. During the commissioning kickoff meeting, the CxA should take additional time to emphasize the importance of the system verification checklists and to discuss the appropriate timelines in which the checklists should be completed. I usually discuss having the checklists completed (as much as possible) 72 hours prior to startup of the equipment. It has been also very helpful on past projects to discuss the uses and value that system verification checklists can bring to the team.

Depending on the SVC, they can be utilized during the design and submittal phase of the project to catch any unwanted changes between the specified product data and the submitted product data for a piece of equipment. This function of SVCs is only useful if the CxA is brought onboard at the appropriate phase of the project.

SVCs for Safe Equipment Testing

The primary use of an SVC is to prevent any unsafe startup of the associated equipment. An SVC should have line items referencing safety measures that need to be in place prior to a piece of equipment being turned on. For electrical equipment this could mean cables have been torqued and insulation resistance testing has been performed; for mechanical equipment this could mean static pressure safeties are in place. An SVC that has been used correctly should almost always prevent catastrophic failure of equipment. Not only will this ensure the equipment is safe, but most importantly it can prevent any serious injuries to members of the Construction Team.

Tracking Project Status with System Verification Checklists

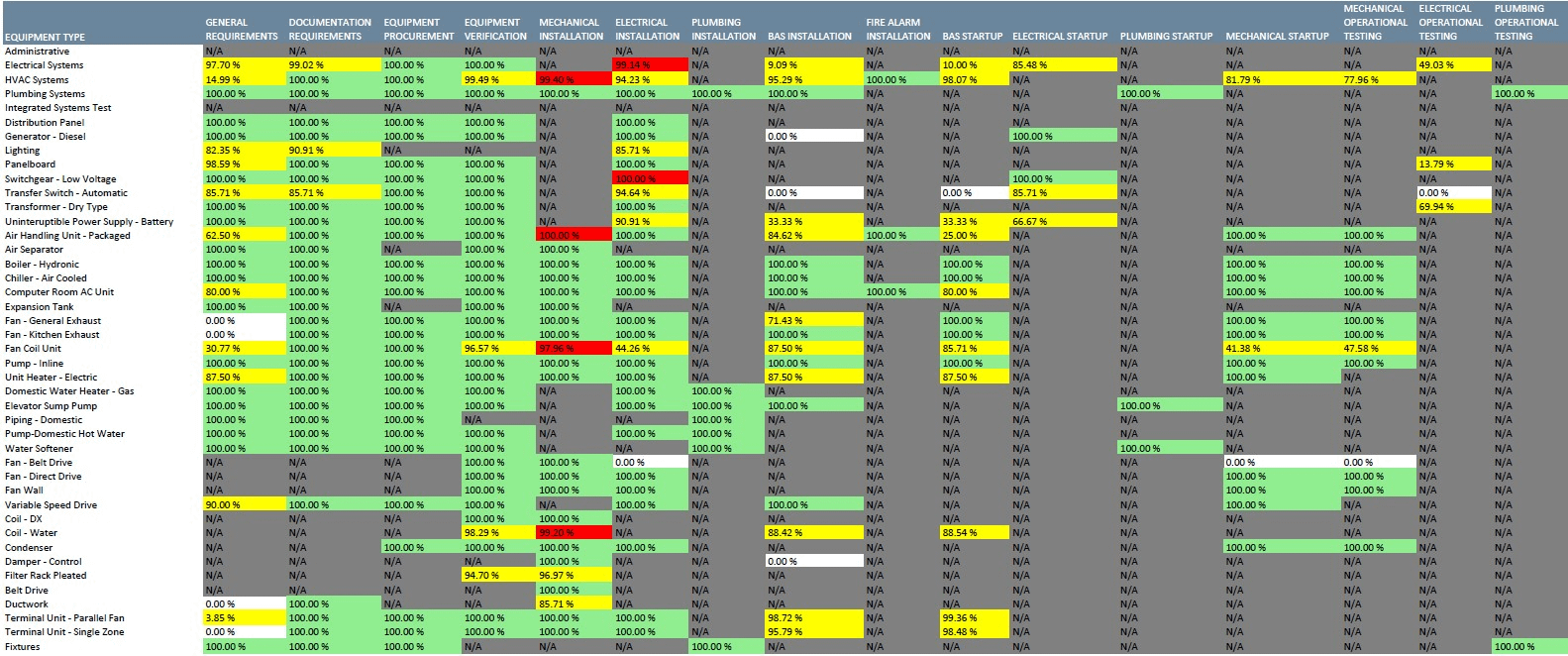

Another major value SVCs bring to the table is that they can be used to generate a very accurate representation of current project status. This depends heavily on each subcontractor completing their associated line items after finishing the work in the field. SVCs should be used to evaluate the current installation of a piece of equipment. If this process is followed, the SVC can help the entire Project Team track actual project status in relation to the project schedule. Many commissioning software systems can utilize an overall progress reporting, similar to what is shown in Figure 1. This data collection can be issued to the team on regular basis and can provide all members of the Project Team with a more defined representation of activities taking place in the field. The data can also be compared to updated project schedules to see if dates are being met or if project deadlines are slipping.

A fully completed checklist should signify that the associated piece of equipment is ready for test and balance activities or if functional performance testing is ready to begin. This is where a CxA must be upfront with the Construction Team and reiterate that no functional testing will be performed until the associated checklists are 100% complete. With appropriate backing from the Owner and General Contractor, the SVC will be completed in advance of any testing.

System verification checklists continue to be a pivotal part of the commissioning process and provide unquestionable value to a project. CxAs must continue to emphasize the importance of SVCs and ensure Project Team members have every opportunity to succeed in assisting in all commissioning activities.

Figure 1 – Sample System Verification Checklist Progress Report

Written by EAB teammate, Cooper Smith.