Walt Lipski founded Engineered Air Balance Co., Inc. in 1955 as the nation’s first provider of independent balancing services. Jim Reid joined him the next year and together this pathfinding duo embarked on a series of firsts.

Walter (Walt) L. Lipski served as EAB’s first President for 29 years.

The term Total System Balance was coined, which Associated Air Balance Council (AABC) holds forth as the benchmark for the profession.

EAB was awarded the Women and Children’s Building at Baylor Hospital in Dallas in late 1958. Ever since then EAB has been involved within the Baylor Hospital system, helping them expand and maintain requirements for healthcare facilities.

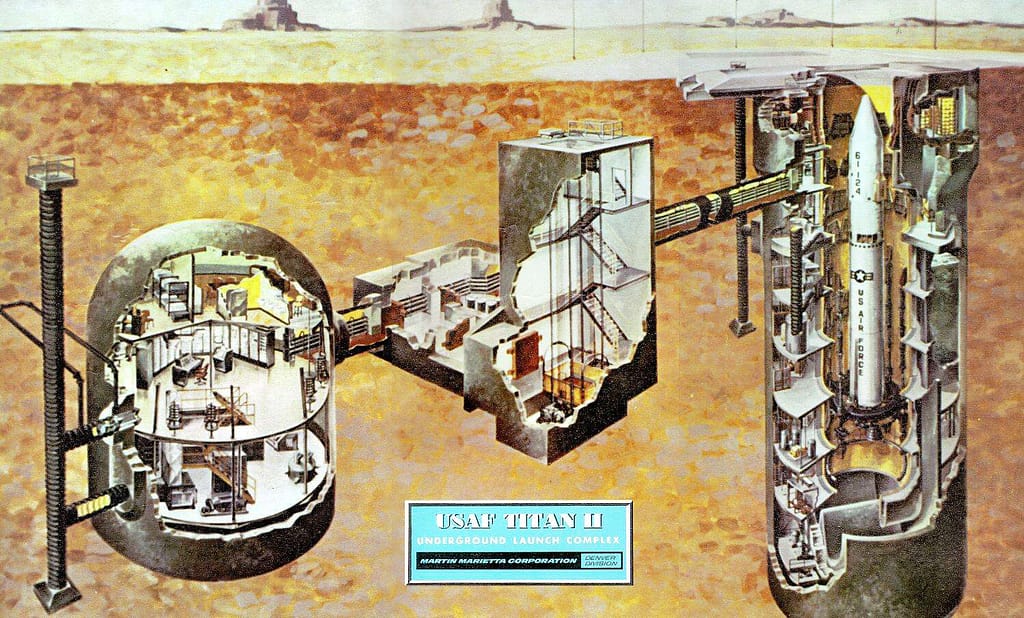

EAB pioneered the methods to pressurize Titan II nuclear missile silos and performed testing and balancing on 34 of the 50 sites located across the nation.

It all started in February 1962 when EAB met with the Corp of Engineers at Vandenberg Air Force Base.

A small group of testing and balancing agents co-founded AABC, the industry’s first certifying agency. EAB was an original member.

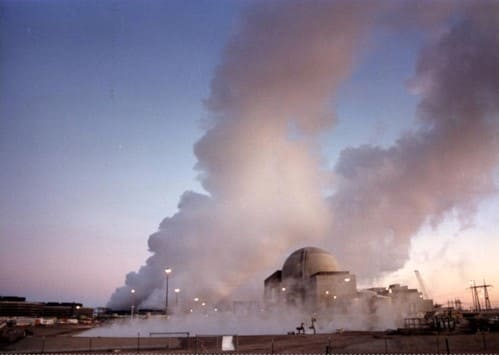

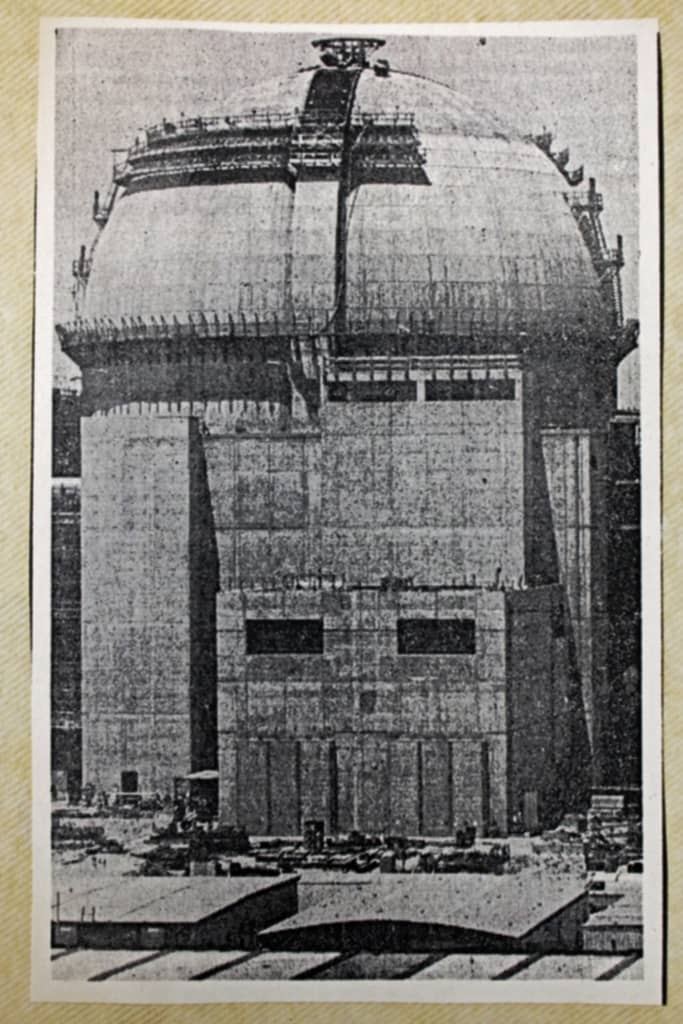

Arkansas Nuclear One in Russellville, Arkansas is a two-unit pressurized water nuclear power plant. Arkansas Nuclear One was the first nuclear plant EAB was awarded. This project provided the necessary experience for additional nuclear generating station opportunities. EAB worked on the second reactor starting with the P&ID drawings and continued until the second reactor was successfully completed.

Engineered Air Balance expanded its services to a second Branch Office, located in Houston, Texas. The Houston office was managed by Gaylon Richardson from 1977 to 2015. Justin Garner was promoted to Branch Manager of the Houston Office in 2015.

The procedures we developed during this project for verification of calibration of instrumentation, specific balancing methods and flow diagrams of systems are still used today to keep the station operating safely and efficiently.

The Bexar County Jail project, testing smoke control systems for jails, resulted in the development of ASHRAE guidelines for commissioning smoke management systems which was approved in 1994.

Our third office was opened in San Antonio in 1991 and managed by Gaylon Richardson. Gary Miller was promoted and served as Branch Manager of the San Antonio Office from 2001 to 2015. Daryl Norris was promoted to Branch Manager of the San Antonio office in 2015.

In preparation of the Alamodome’s opening in May of 1993, EAB was hired to verify the temperature control system while the facility was set up for football, basketball, hockey and concerts.

Our findings were used by ASHRAE’s fire/smoke committee to revise the mathematical models for all large-volume public assembly spaces.

EAB’s smoke control testing using electronic actuators on smoke and fire dampers lead to the UL revising their standards and made it a requirement to do torque testing on actuators. The comprehensive smoke control testing also prompted NFPA to update their NFPA Standards 90 A&B.

EAB staff members contributed to AABC’s 2002 National Standards for Total System Balancing.

The Cynthia Mitchell Basic Science Research Building on the University of Texas M.D. Anderson Cancer Center campus was completed in September 2005 to further research in the areas of immunology, molecular biology and human cancer genetics.

Galveston National Laboratory (GNL) is a high security National Biocontainment Laboratory housing several Biosafety level 3 and level 4 research laboratories.

EAB copyrighted their in-house Testing, Adjusting and Balancing Procedures Manual.

EAB made the decision to pursue Building Commissioning Services that would go beyond HVAC systems and offer its clients a commissioning process servicing all equipment and assemblies in modern buildings.

Since that time, EAB has built upon its TAB experience to create an outstanding team of dedicated commissioning professionals with expertise in mechanical, electrical, plumbing, building control systems and life safety systems.

Gaylon Richardson served as EAB’s fourth President for 10 years.

EAB moved to a Visionary Culture and redefined EAB’s Mission, Vision and Core Ideologies.

EAB had the privilege of working on one of the largest new hospital campuses in the United States. The 1.7 million square foot facility in Indianapolis contains 315 inpatient beds, 19 operating rooms, and several additional specialized treatment areas. The hospital links functionally and operationally to the adjoining Eskenazi Health Outpatient Care Center, which contains 110 exam rooms. The project also includes a 2,700-car parking garage.

Due to the out of state location and EAB’s commitment to quality, our team relocated to Indiana for the duration of the 2-year project ensuring its overall success. Because of EAB and the other project team members’ efforts, Eskenazi Health’s downtown campus achieved LEED Gold certification in 2015. The improved indoor air quality was a significant factor in this achievement.

Our team witnessed firsthand a need for quality Critical Environment Certification (CEC) services for our clients. Because of our expertise in critical environment HVAC systems, we made the decision to provide limited CEC services for existing clients and develop our CEC program.

EAB opened the Training Center in Spring, Texas, to train staff, engineers, contractors, Commissioning and Testing and Balancing personnel outside of EAB.

Kevin Underwood currently serves as EAB’s fifth President.

Due to the growth in Critical Environment Certification services, EAB formally established it as a separate service in addition to TAB and Building Commissioning.

Baylor University Medical Center at Dallas is a nationally recognized faith-based, not-for-profit hospital that cares for more than 300,000 people each year. Serving as the flagship hospital of Baylor Health Care System, Baylor Dallas is a major center for patient care, medical training and research in North Texas, having 1025 licensed beds.

EAB was awarded the Women and Children’s Building at Baylor Hospital in Dallas in late 1958. Ever since then, EAB has been involved within the Baylor Hospital system, helping them expand and maintain requirements for healthcare facilities.

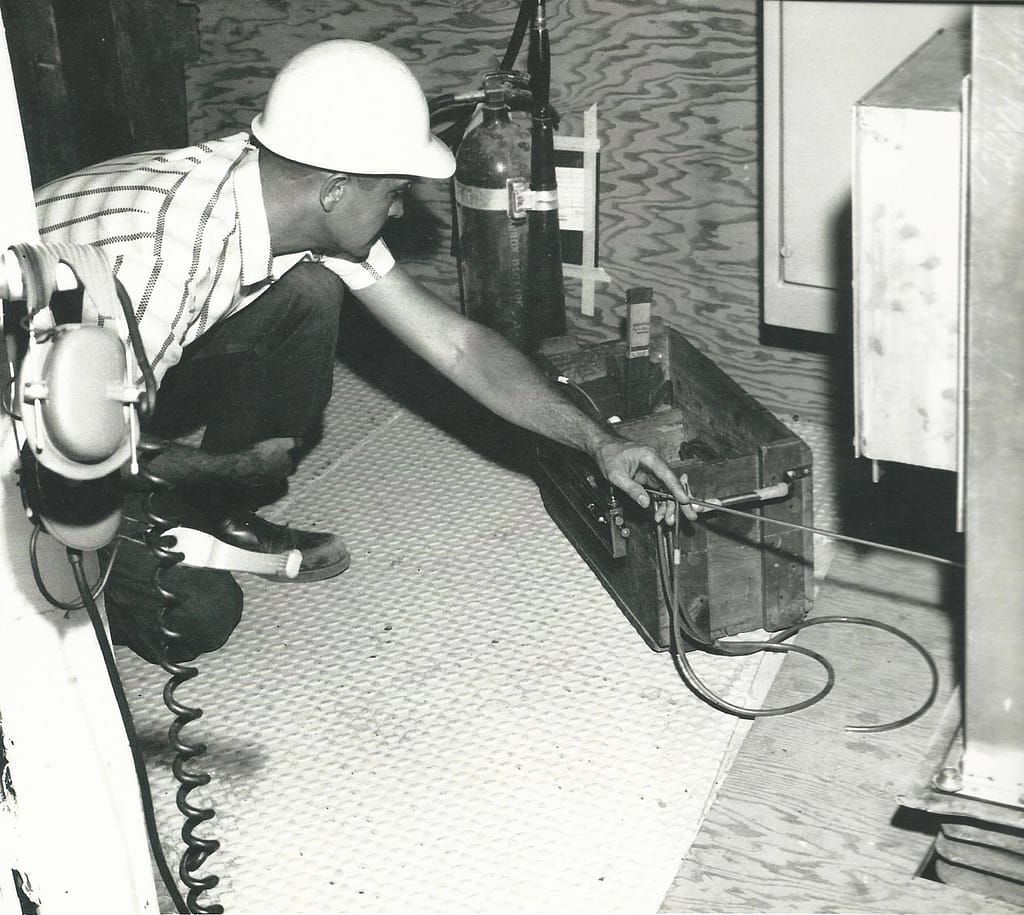

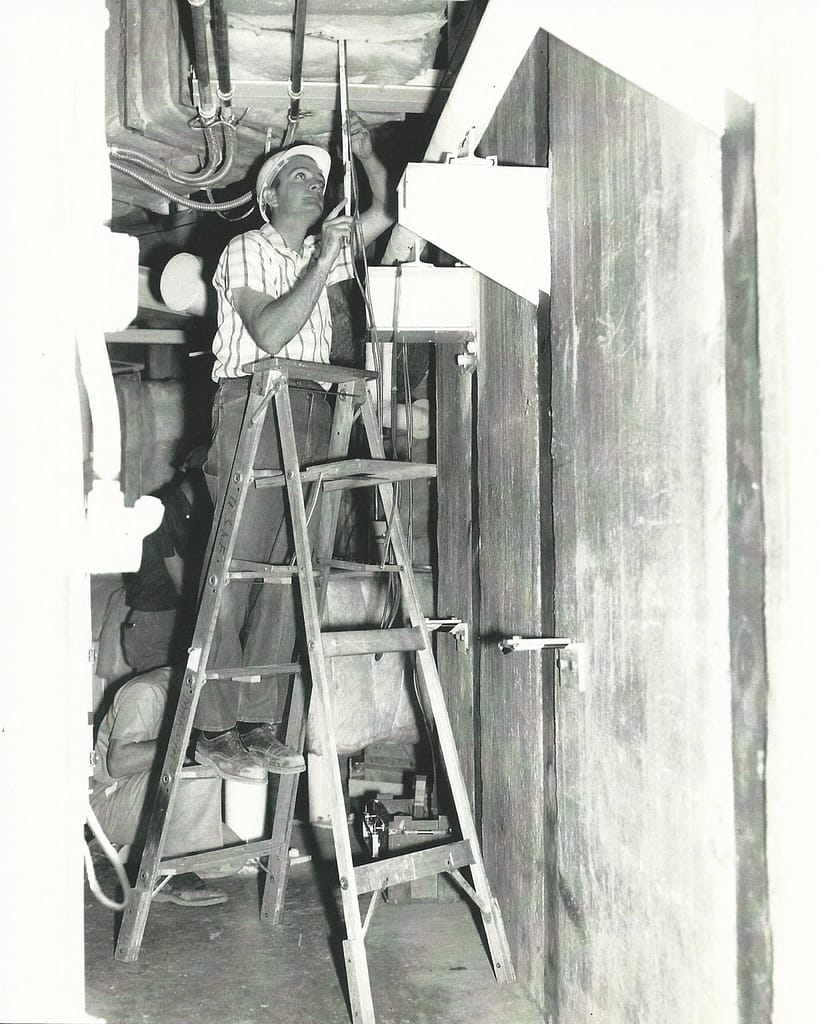

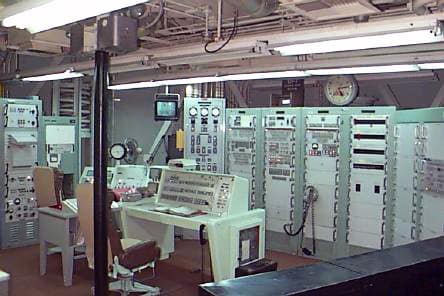

In February 1962, EAB met with the Corps of Engineers at Vandenberg Air Force Base. After describing our services, EAB was notified to proceed with the first of three Titan II sites at the base. After the balancing was complete, the Corps of Engineers were notified that EAB was ready to validate the air quantities. The validation process started at 8:00am and was completed at 6:30pm. At 7:30pm, EAB presented the test data to the Corps of Engineers. Walt Lipski explained the systems and verified the quantities met design criteria.

After a brief discussion, the data was accepted by all parties. However, Walt discovered that the control room was not isolated from the support area and the support area was not isolated from the missile chamber. As a result, arrangements were made the next day for the three chambers to be isolated and balanced.

EAB was awarded the remaining two sites at Vandenberg, 18 sites in Tuscon, Arizona and 12 sites in Little Rock, Arkansas.

EAB pioneered the methods to pressurize Titan II nuclear missile silos and performed testing and balancing on 34 of the 50 sites located across the nation.

Palo Verde Nuclear Generating Station has three 1270-megawatt nuclear reactors and is located in Tonopah, Arizona on 4,000 acres. The station is a major source of power for Phoenix and Southern California, capable of serving 4 million people. This is the only nuclear generating facility in the world that is not located adjacent to a large body of above-ground water. In fact, the station annually uses 20 billion gallons of gray water, recycled from wastewater plants, for cooling pumps that process 111,000 gallons per minute.

Our testing identified temperatures in the containment building ranging from 133˚F at the higher level and 69˚F at the bottom level, beyond the maximum threshold of 120˚F. After performing troubleshooting and infrared testing, we recommended modifications to the insulation that reduced the temperature stratification to a range of 116˚F to 86˚F.

The procedures we developed for verification of calibration of instrumentation, specific balancing methods and flow diagrams of systems are still used today to keep the station operating safely and efficiently. These methods and procedures were performed under the umbrella of the Nuclear Regulatory Commission.

The Alamodome is a multi-purpose entertainment stadium with 65,000 seats, expandable to 72,000 seats, in San Antonio, Texas. Its distinctive design features a 9-acre roof hanging from four 100-foot masts. The arena can be arranged in 24 different possibilities and has two Olympic-sized, permanent ice rinks that meet professional standards for hockey, figure skating and speed skating.

In preparation of the Alamodome’s opening in May of 1993, EAB was hired because of our specifically trained and equipped team of experts. To deliver an optimum operating facility, the temperature control system was tested while the facility was set up for football, basketball, hockey and concerts. EAB tested and balanced the HVAC systems, verified HVAC control point and sensor calibration and performed HVAC control sequence verification.

In addition to testing and balancing, EAB was exclusively requested for a special project to assess the smoke control system by building a fire, demonstrating to the fire marshal that in the event of an actual fire the occupants had sufficient time to exit before the smoke plume fell from the 170-foot-high ceiling to the seating area. EAB built a controlled 10-megawatt fire with an equal amount of smoke. EAB led the project team, hired a smoke control consultant to assist with the implementation of the fire and smoke, and hired a research team to analyze the data trends by measuring the temperature of the rising smoke plume and the temperature spread across the roof.

Our beneficial findings were used by NFPA and the ASHRAE technical committee for smoke control system design to revise the mathematical models for all large-volume public assembly spaces, impacting the design of large smoke control systems for years to come.

The Cynthia Mitchell Basic Science Research Building on the University of Texas M.D. Anderson Cancer Center campus was completed in September 2005 to further research in the areas of immunology, molecular biology and human cancer genetics.

During the control sequence verification of the laboratory and vivarium systems, EAB identified the need and developed an integrated system test procedure that documents the control of all systems when the electrical system went from normal power to emergency power and back to normal.

Because the Owner was particularly concerned about maintaining constant pressure in the vivarium to prevent contamination, we performed integrated system tests on those levels multiple times until the start-up sequences provided the correct pressurization.

Galveston National Laboratory (GNL) is a high security National Biocontainment Laboratory housing several Biosafety Level 3 and Level 4 research laboratories.

Located on the University of Texas Medical Branch campus, this 196,000-square-foot building is a national resource for developing therapies, vaccines and diagnostic tests for microbes that might be used by bioterrorists, and for analyzing naturally occurring, emerging infectious diseases such as SARS and West Nile Virus.

EAB began work in 2006 reviewing the design documents at each design milestone for balance-ability, reviewed submittal data and performed construction observations prior to implementing complete HVAC system testing.

EAB wrote the functional performance test and the integrated system test for the HVAC systems. The integrated systems test included emergency power testing and security testing.

The Integrated System Test required multiple trends to verify the exhaust system started before the supply system without over-pressurizing.

The Functional Performance Testing resulted in recommendations to change the design control sequences to meet the system revisions and resolve the control and room pressure issues. The project was completed October 1, 2009, and launched EAB into the Building Commissioning Industry.