On a recent project we had the opportunity to work on an elementary school renovation that upgraded the chilled water plant. The new chilled water plant consisted of two new water cooled chillers, one new cooling tower, an existing air cooled chiller, and associated pumps. The chilled water plant is sequenced to operate in a constant primary configuration. We were contacted by the Engineer of Record (EOR) and Mechanical Contractor to assist with troubleshooting after both water cooled chillers failed factory start up. The main issue was that both chillers constantly lost condensing water flow during startup and the cause of the problem could not be determined.

On a recent project we had the opportunity to work on an elementary school renovation that upgraded the chilled water plant. The new chilled water plant consisted of two new water cooled chillers, one new cooling tower, an existing air cooled chiller, and associated pumps. The chilled water plant is sequenced to operate in a constant primary configuration. We were contacted by the Engineer of Record (EOR) and Mechanical Contractor to assist with troubleshooting after both water cooled chillers failed factory start up. The main issue was that both chillers constantly lost condensing water flow during startup and the cause of the problem could not be determined.

Cleaning the Sump Pump Basin

Cleaning the Sump Pump Basin

The first issue that occurred with this new plant was that the new chillers would initially achieve condensing water flow but would then slowly drop below the minimum design requirement. We attempted to recreate the startup scenario on the condensing water system to determine the issue. After taking serval pressure drops among the condensing water piping and verifying the pumps curves to the submittal, it was determined there was a restriction on the entering side of the vertical lift pumps. Since these pumps utilized a sump basin, we concluded that trash and debris had gotten into the sump basin. We told the Mechanical Contractor that once the pumps energized, the trash would slowly be drawn and pulled to the end suction diffuser; we suggested they consider cleaning the sump basin. Once the debris was cleared from the basin, flow was re-verified on the chillers and condensing water pumps. Upon resolving this issue, another issue surfaced.

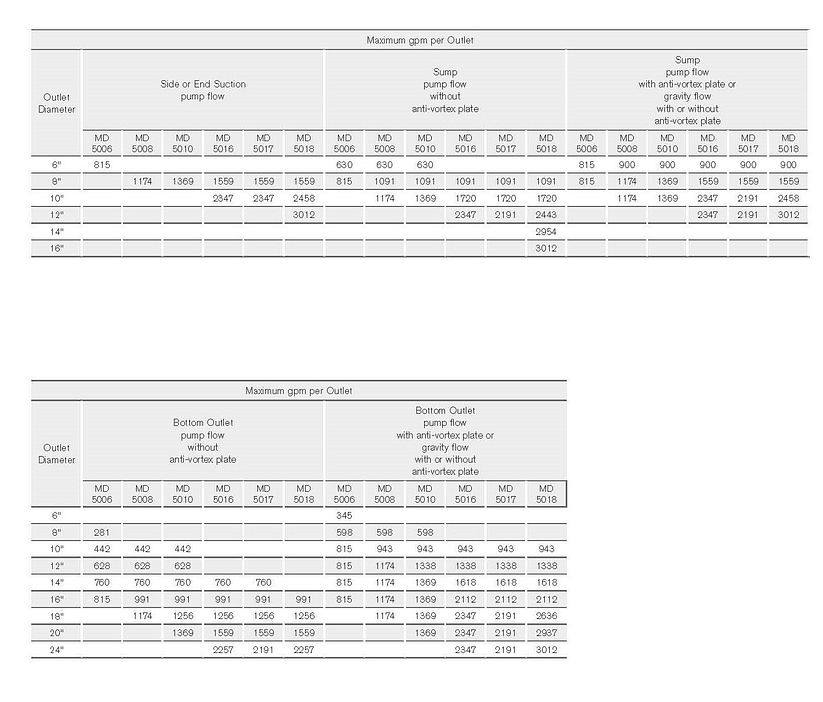

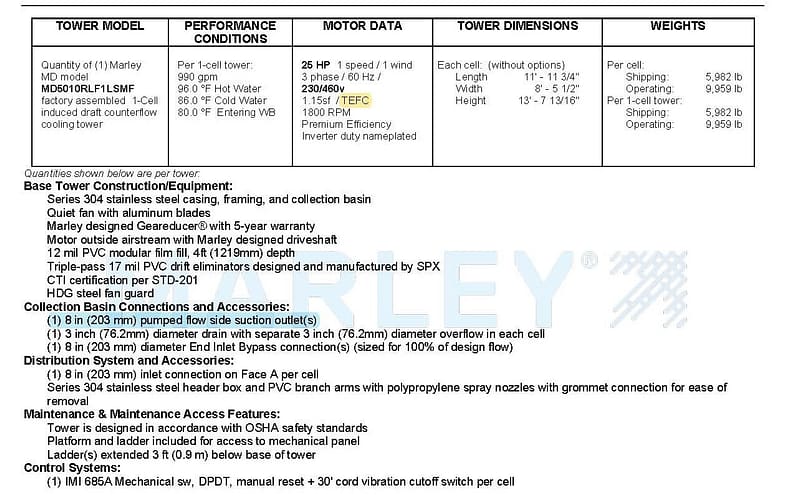

Piping Configuration

Piping Configuration

The cooling tower was also provided with an 8” side connection at the bottom of the collection basin. After making the necessary piping configuration changes, the Mechanical Contractor was able to also utilize this side connection, along with the gravity flow drain, to properly drain the tower when both chillers were utilized simultaneously. In conclusion, this was a unique opportunity to demonstrate our troubleshooting and technical skills for the EOR, Mechanical Contractor and Owner.

Written by Alvin Beddingfield, Jr.

Piping Configuration

Piping Configuration