Domestic hot water systems are practically a requirement in modern day construction and design. These systems supply conditioned tempered water throughout a building for occupant use and comfort. Hot water systems can serve bathroom fixtures for hand washing or domestic hot water in kitchens for cooking, cleaning and disinfecting. Temperature requirements may vary from state to state, but the requirement codes for domestic hot water systems make them much larger when capacity and redundancy for are taken into account. With all large thermal systems, there is more of a danger than small capacity systems. The bigger the system, the more important it is to perform commissioning services to be sure all system piping and components are installed as designed and in the correct piping configurations.

Thermal Expansion and Pressure in Closed Plumbing Systems

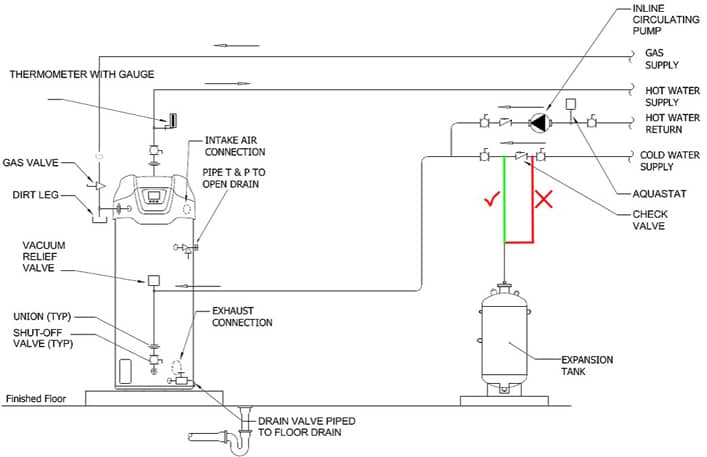

Water, like many other mediums, expands and contracts with higher and lower temperatures, respectively. This causes pressure issues when it involves closed plumbing systems (where the makeup plumbing has a check valve installed, preventing the backflow of any medium upstream into the supply). When the water temperature in the domestic water heater is below setpoint the equipment will enter into the heating sequence. During this time, the heater will transfer thermal energy into the fluid inside of the tank. (The tank capacity is a major factor in the thermal expansion requirements of a heating system). Assuming there will be no demand downstream and the system remains closed, the fluid slowly expands as the temperature of the water increases. If the heater is piped directly to a single local source, the heater capacity will only come into consideration. If there is a hot water loop, the added capacity of the water in the recirculation loop will also be heated. The full capacity of the system should be accurate when calculating the expansion requirements of the system.

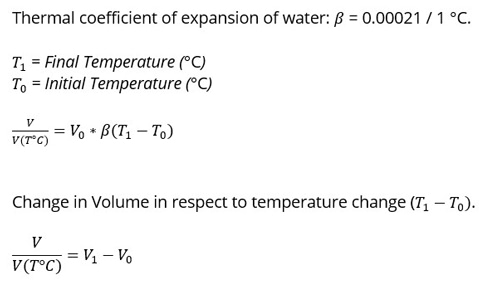

The following equation shows the expansion rate of water:

Preventing Thermal Expansion Hazards

Throughout all closed plumbing systems tested, there are two items required to be plumbed correctly to prevent a thermal expansion explosion in any water based thermal system. These items are called the thermal expansion tank and the pressure relief valve (PRV). If the expansion tank is installed in the system correctly, the PRV will remain an emergency prevention component. As more systems are tested, the thermal expansion tank seems to be the one device consistently installed incorrectly. A thermal expansion tank is a device that allows thermal expansion to take place without a tremendous amount of increase in pressure. This device involves a rubber bladder in a pressurized reservoir. For this tank to absorb the thermal expansion, it needs to be piped into the closed system which is anywhere downstream of the check valve installed in the cold water makeup piping. This is the same device that makes a particular system a closed versus an open system. When this device is piped upstream of the check valve, the check valve prevents the expanding water from entering the tank. The diagram below shows the correct location to install an expansion tank in respect to the check valve in the cold water makeup piping.

With so many domestic water systems found to be installed incorrectly, it begs the question if the proper training is being supplied to construction industry workers. This shows the importance of contracting a commissioning team with a full understanding of how systems function.

Written by EAB Teammate, Jordan Ourso.